Trigeneration System Design

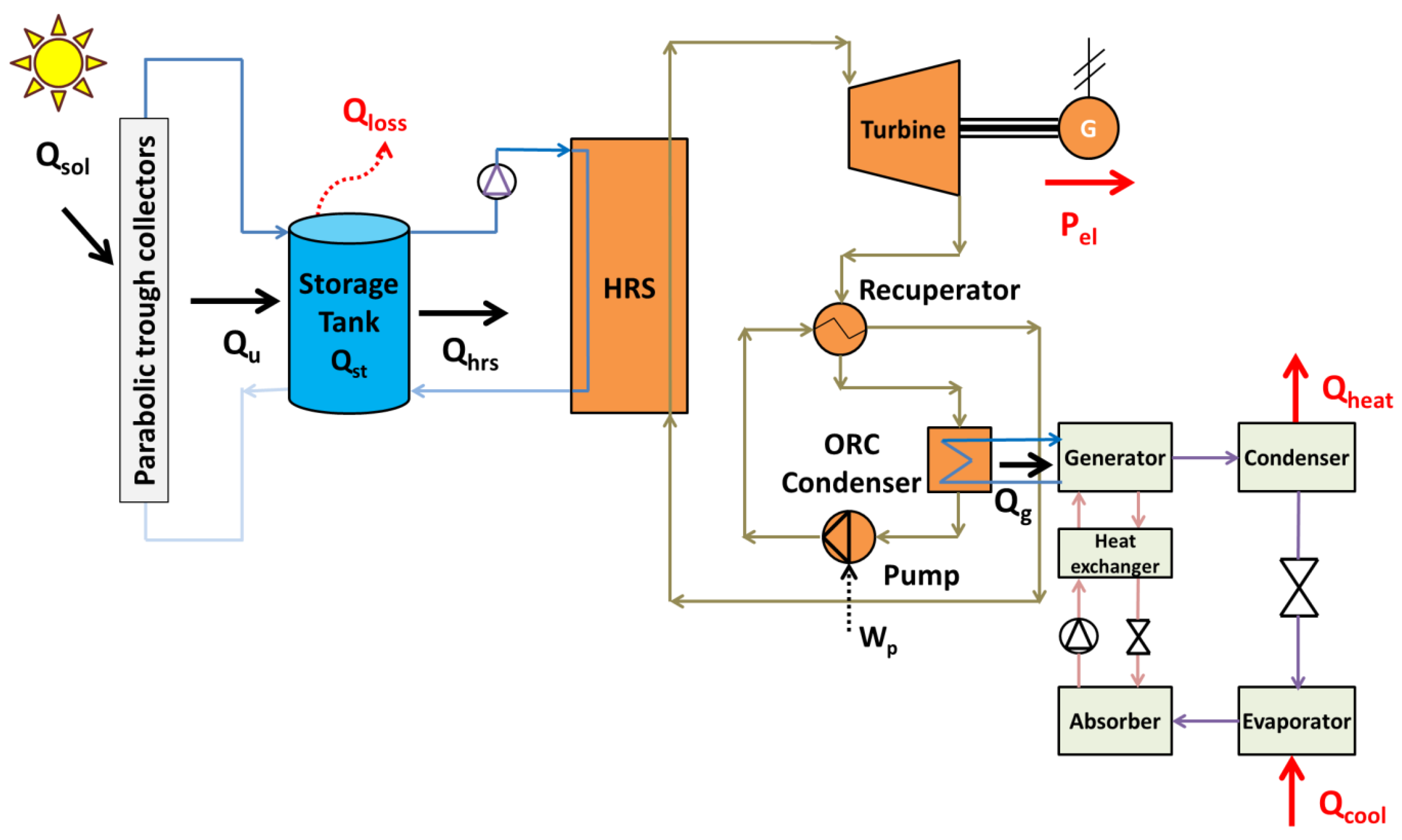

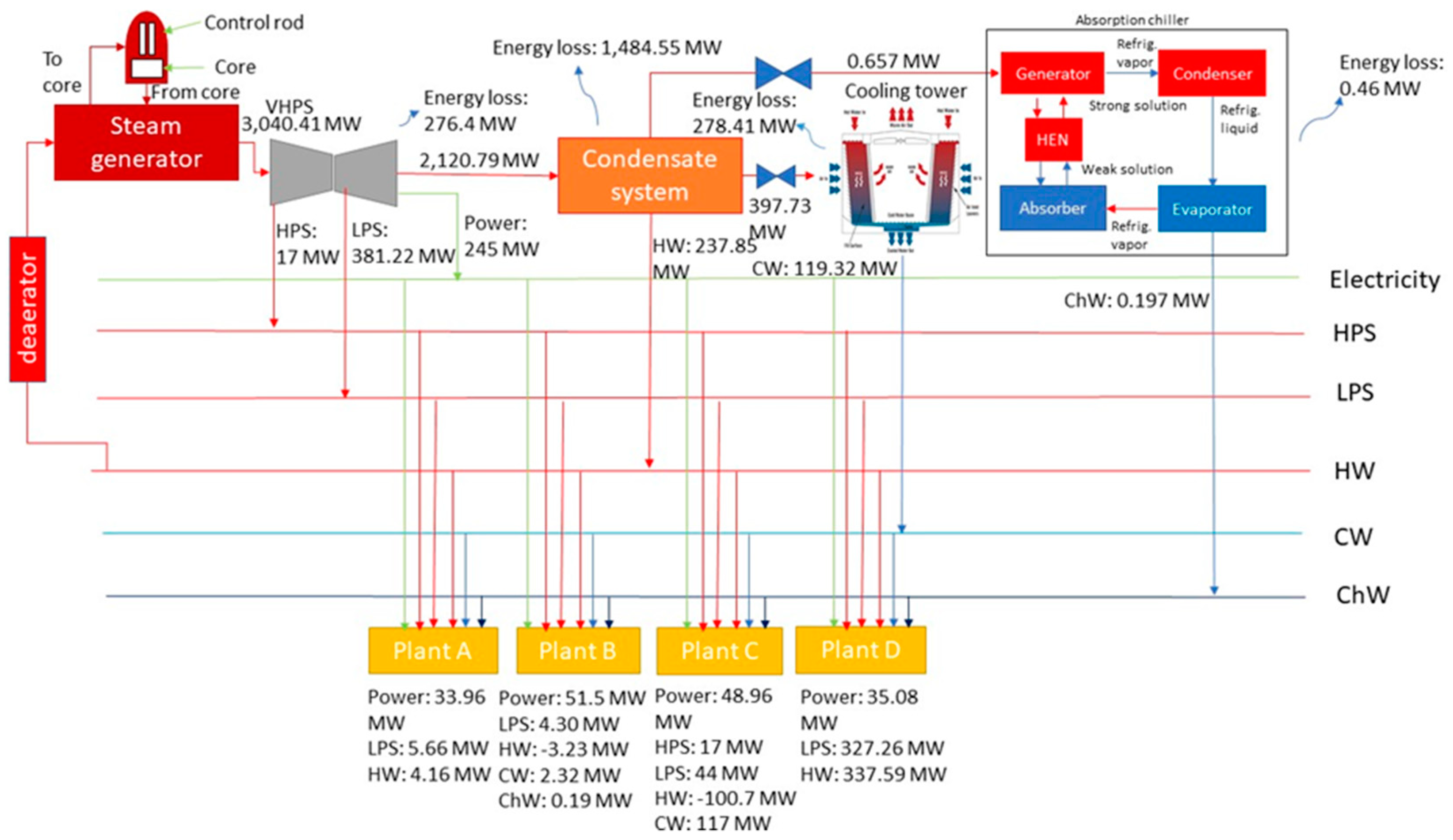

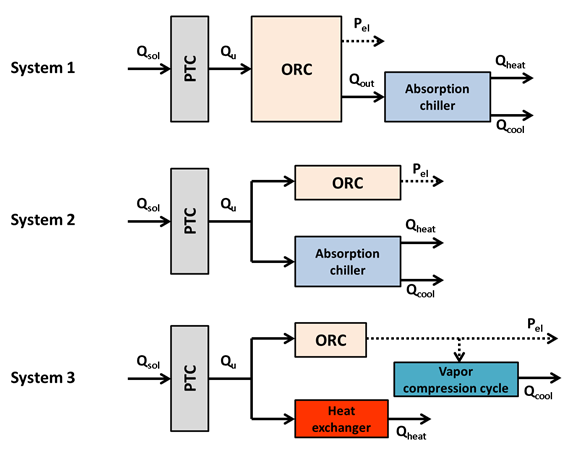

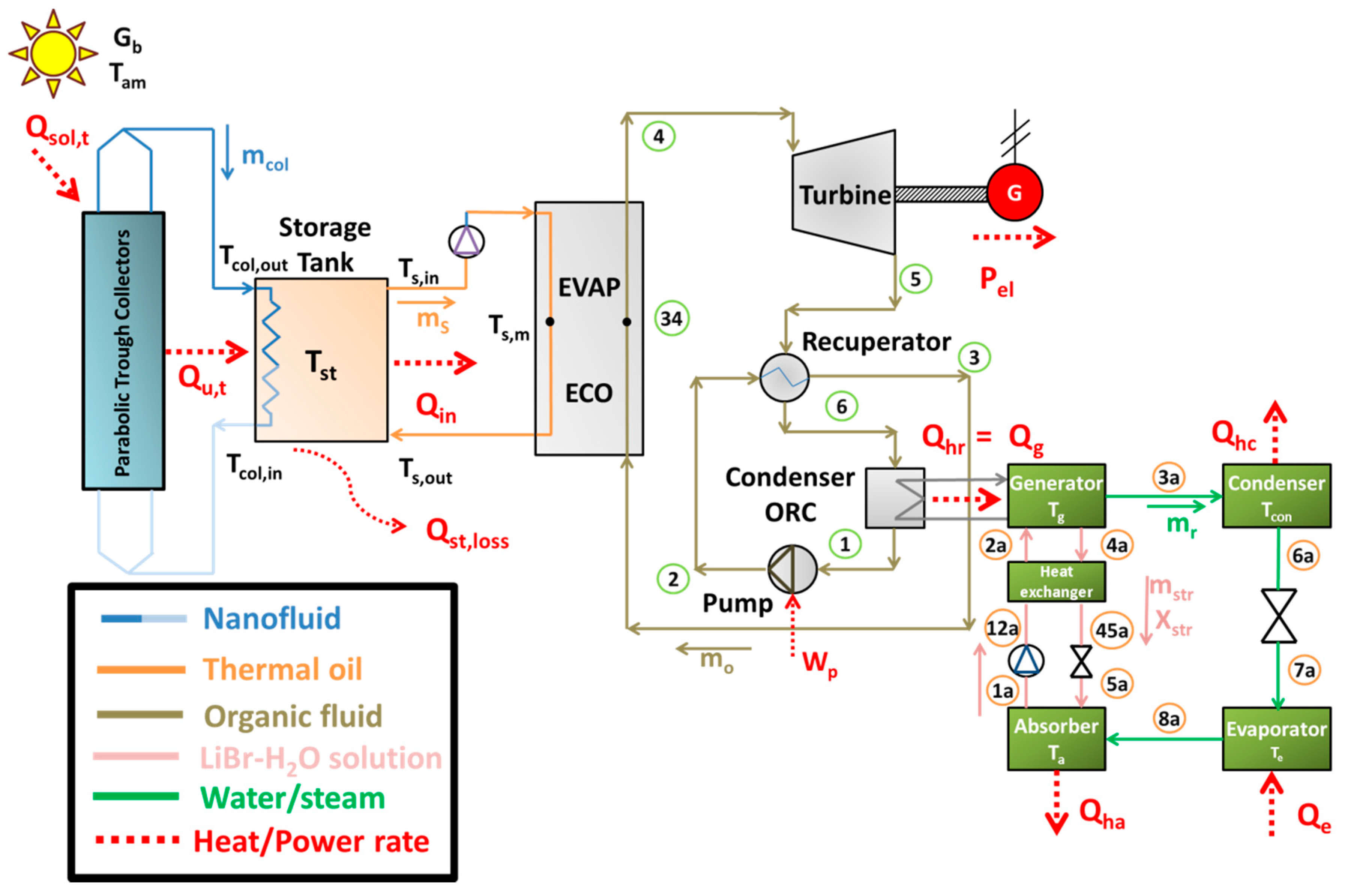

Trigeneration system design. Micro-Trigeneration M-CCHP is designed and sized to provide all the benefits of box-car sized Trigeneration to smaller footprint properties such as retail stores restaurants warehouses and office buildings. The advantages of Trigeneration system over conventional generation system using of LPG were confirmed after of number of trials of current Micro-Trigeneration system according to 3 as below. This work is aimed at the development of a systematic procedure for energy conservation through the integrated design of trigeneration systems combined cooling heating and power CCHP while incorporating solar energy as a renewable form of energy with low GHG emissions.

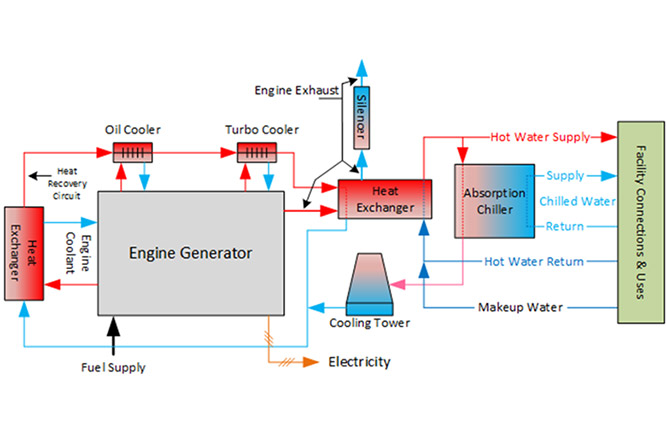

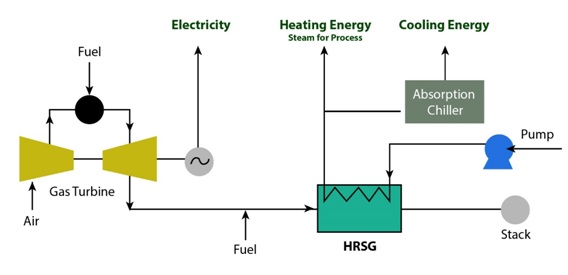

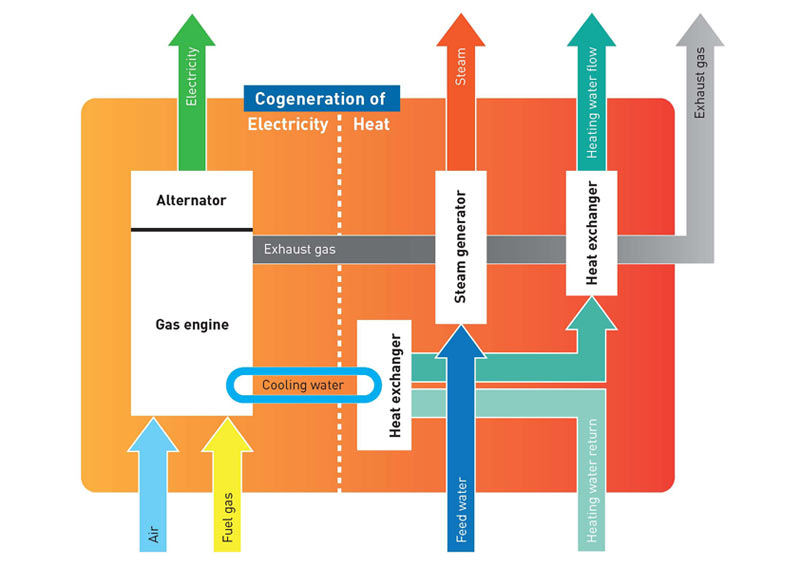

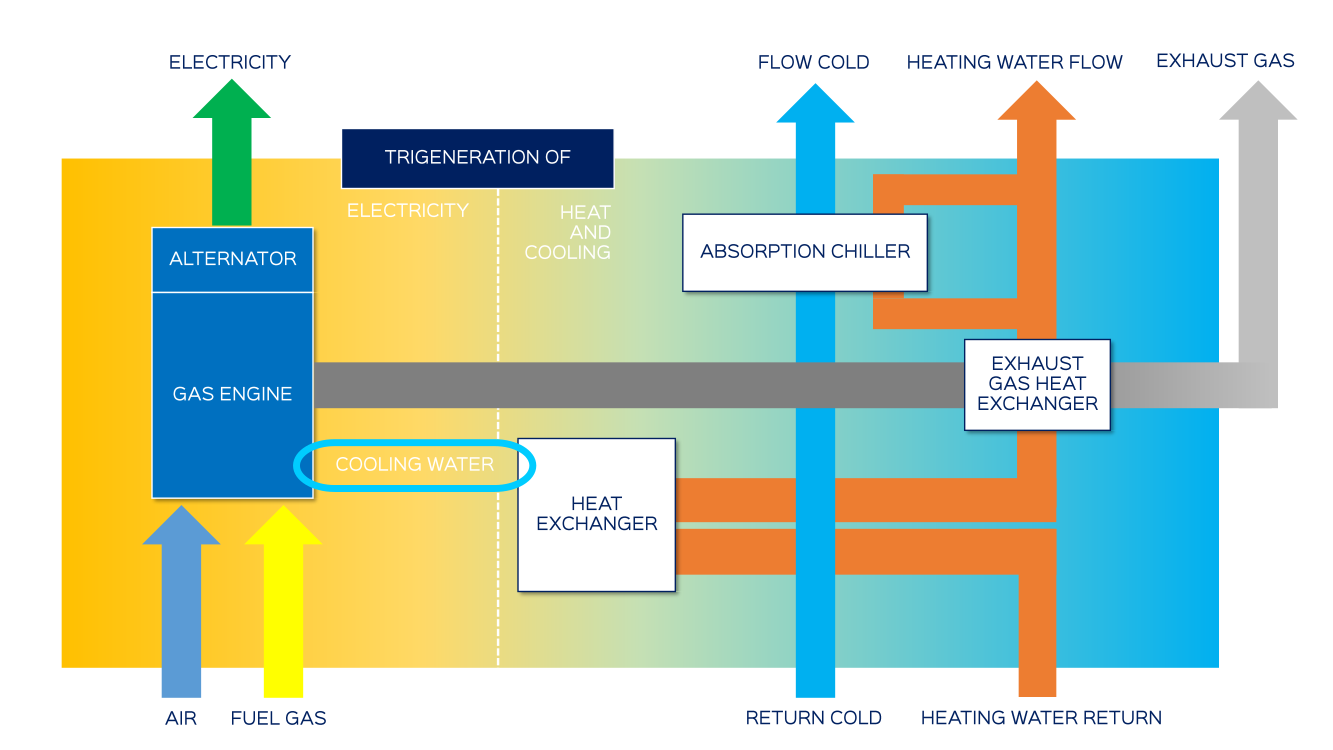

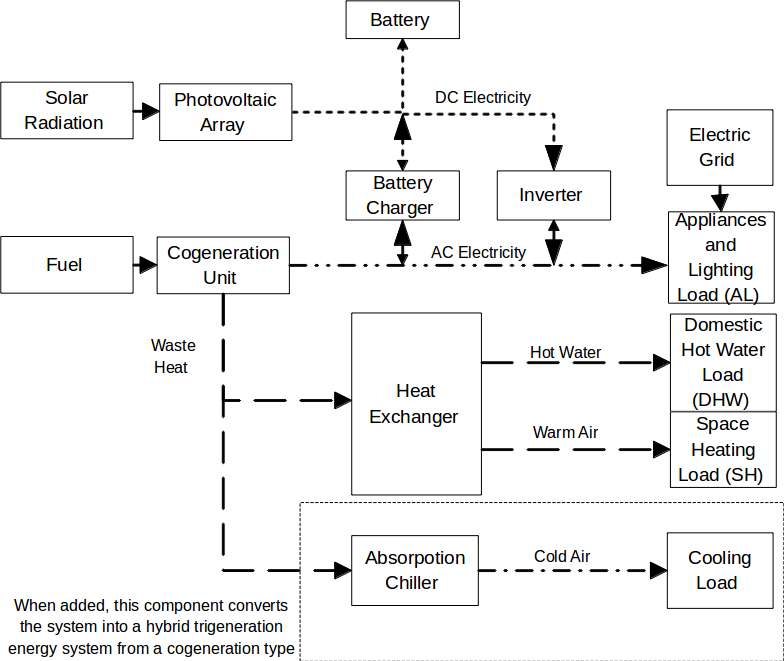

The technology behind trigeneration is fundamentally based on the coupling of a cogeneration module with an absorption chiller. GENERAL SYSTEMS DESIGN INC. Natural gas and biogas-based cogeneration-trigeneration solutions which are preffered mainly by the industrial plants can meet electricity heating and cooling needs of the facilities at the same time with high energy efficiency and deliver significant cost advantages to the companies.

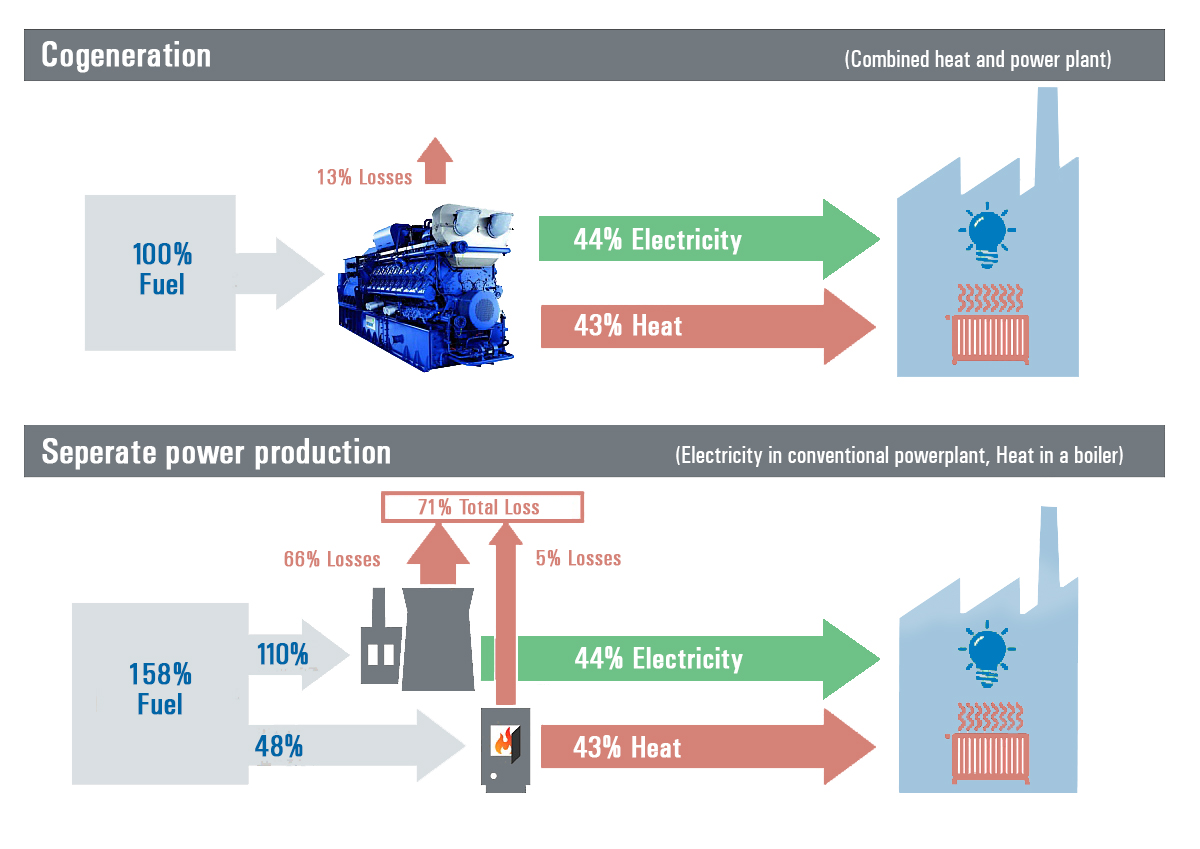

That is why we offer our MEP design services. TEKSAN thanks to its solid experience and know-how delivers high performing natural gas and. Conventional coal or nuclear-powered power stations convert only about 33 of their input heat to electricity.

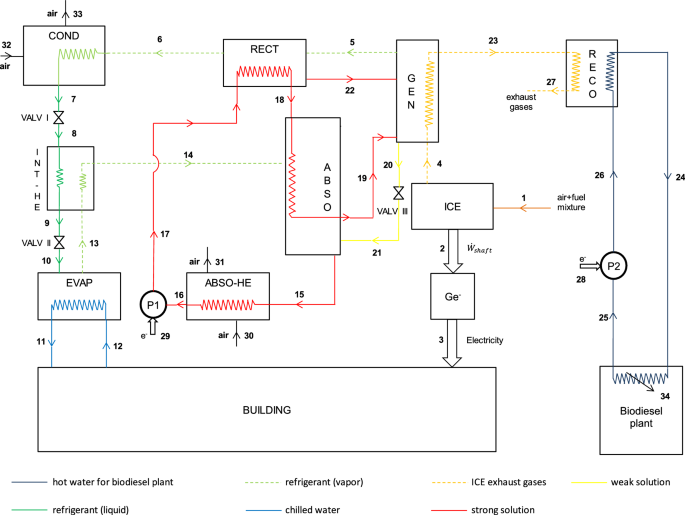

Trigeneration or combined cooling heat and power CCHP is the process by which some of the heat produced by a cogeneration plant is used to generate chilled water for air conditioning or refrigeration. The tri-generation system was made of a CHP unit and a heat-driven ejector cooling system. The trigeneration system reduces the heat offtake from the heat exchanger station of the heating plant reduces the cost of electricity needed for indoor air conditioning and generates electricity for its own consumption.

Tri-generation systems are considered as an alternative for warmer climates. We have designed many Cogeneration and Trigeneration systems which enables us to work closely with you and your consultants to provide the best solution to you individual requirements. Because of its complexity your design needs to be absolutely flawless if you want your system to work.

The BROAD BDH absorption refrigeration unit enables the maximum use of CHP units even in the summer months. The 75 saving of operation cost compared to conventional unit. In this work the.

Designed to your requirements. Trigeneration systems are very efficient but complex systems that allow buildings to generate electricity heating and cooling all at the same time.

The advantages of Trigeneration system over conventional generation system using of LPG were confirmed after of number of trials of current Micro-Trigeneration system according to 3 as below.

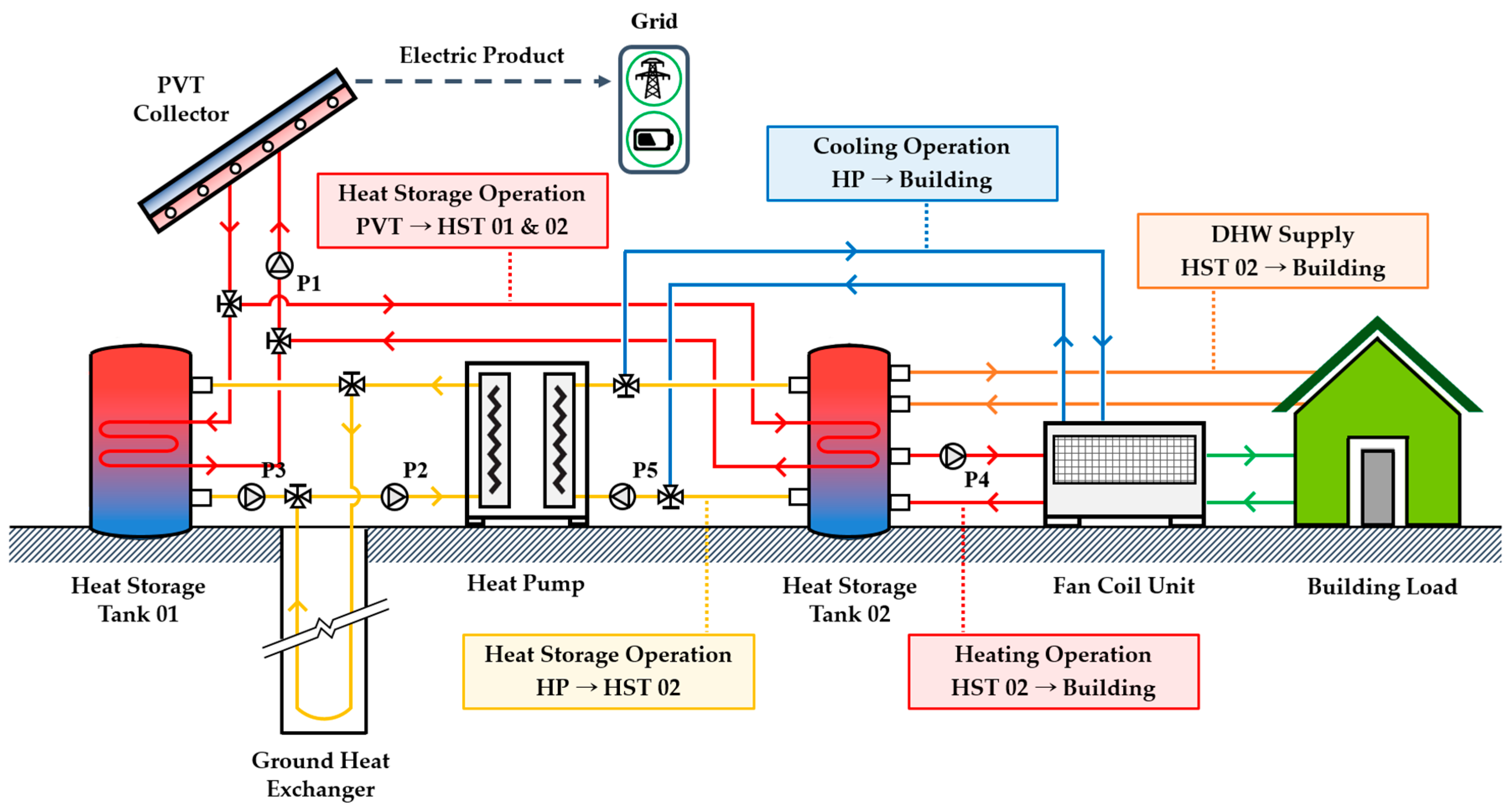

A sound investment An investment in a trigeneration plant starts to pay off when there are seasonal periods when the power plants waste heat can be fully used. The 75 saving of operation cost compared to conventional unit. A sound investment An investment in a trigeneration plant starts to pay off when there are seasonal periods when the power plants waste heat can be fully used. Trigeneration refers to the simultaneous generation of electricity and useful heating and cooling from the combustion of a biomass fuel or a solar heat collector. Tri-generation systems are considered as an alternative for warmer climates. A trigeneration system Figure 1 is designed with the purpose of satisfying the predictable demands of electricity heat for heating and sanitary hot water SHW and cooling of a given consumer center. The technology behind trigeneration is fundamentally based on the coupling of a cogeneration module with an absorption chiller. A typical tri-generation system involves the extension of a CHP plant by coupling a prime mover to thermally driven equipment to produce cooling. By this extension the waste energy from the prime mover can be used to drive both heating and cooling systems.

However the technical ecological and economical aspects of such systems are still largely unexplored. The technology behind trigeneration is fundamentally based on the coupling of a cogeneration module with an absorption chiller. The advantages of Trigeneration system over conventional generation system using of LPG were confirmed after of number of trials of current Micro-Trigeneration system according to 3 as below. Careful design is needed to optimize the plant for the most viable configuration. A TRNSYS mathematical tool was developed to simulate all components of the system in a dynamic process to. TEKSAN thanks to its solid experience and know-how delivers high performing natural gas and. An absorption chiller is linked to the combined heat and power CHP to provide this functionality.

Post a Comment for "Trigeneration System Design"